Workshop

and Overhaul

Rapid turnaround and

minimal inconvenience

Rapid turnaround and

minimal inconvenience

Workshop

and

Overhaul

Rapid turnaround and

minimal inconvenience

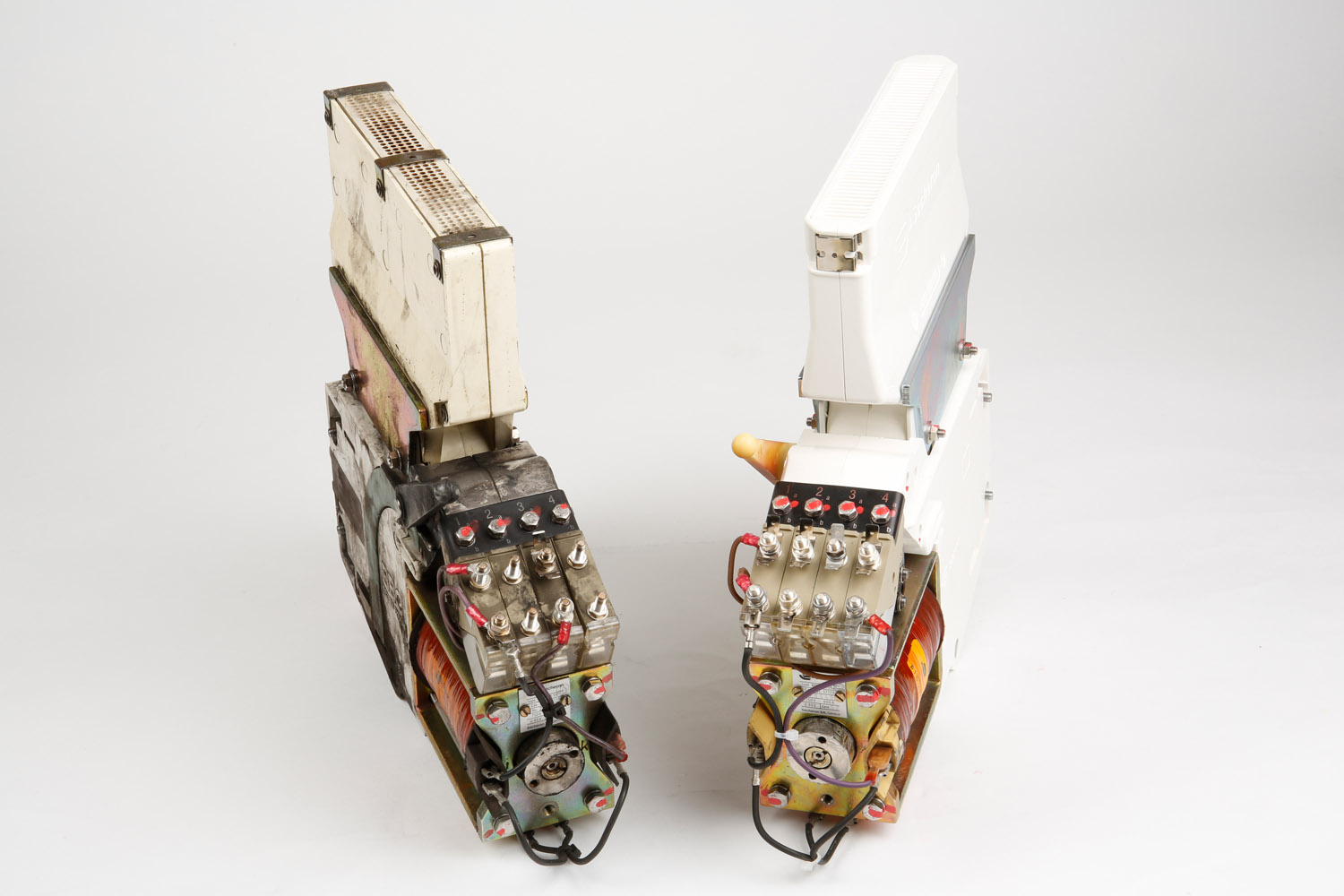

Our workshop offers extensive test and overhaul facilities, with the ability to test high current.

Precision… made here

Our professional engineers have a wealth of global railway knowledge and experience. By growing their experience in the rail industry for many years, our engineering team have the expertise to meet the requirements demanded by the industry standards, our customers and the Safety Approval Authority.

By developing new systems and products from design concept through to in-service maintenance; our engineers work closely with, and help guide our customers throughout the development life cycle.

Rowe Hankins Ltd. is committed to continual improvement, development and growth with a complete understanding of their customer, end-user and future rail market requirements.

Our workshop has extensive facilities including:

Rowe Hankins Ltd. strives to ensure rapid turnaround and minimal inconvenience, downtime and potential penalties that may form part of an active overhaul programme.

We also overhaul and work with products from many other manufacturers due to the increasing demand for economics management of trainborne, rather than replace them with new and expensive parts.

Our experienced OTMR specialists, who operate on OTMR reconfiguration and battery change outs and work on continual product development. They use the latest programme applications and use bespoke solutions to reduce component down-time. With on-site support and pre-service reports available to ensure economic repair of parts or replacement parts supplied, as well as post-service expert reports.