The ideal space – sustainability and reducing operational costs are key considerations.

When looking for logistics, manufacturing, assembly or processing space, you know your operations best and the importance of scalability, layout and flow to ensure efficiency. But coupled with managing operational costs and also meeting environmental, social and governance (ESG) goals can pose additional challenges.

Read on to discover how Build to Suit can help support your ESG goals, or submit an enquiry here to find out more.

Meeting carbon reduction and environmental business targets can easily be achieved when your operational space is designed to do so. We know that sustainability and reducing operational costs are key considerations for our customers. That’s why our build specification ensures all our newly built buildings can carry 100 per cent Photovoltaic solar coverage across the roof, underpinned by additional supporting sustainability features including energy ratings of EPC A and upwards, a minimum industry sustainability BREEAM standard of Very Good. Combined, these offer customers lower running costs, improved energy efficiency and a reduction in their overall operational costs.

The way forward is for the customer and developer to work together. We can help the customer fully understand the ways in which a customised, sustainable building can reduce operational costs, underwrite their green ambitions, and provide their employees with a warm, bright working environment – which is important when you consider that attracting and retaining employees can be a real pain point.

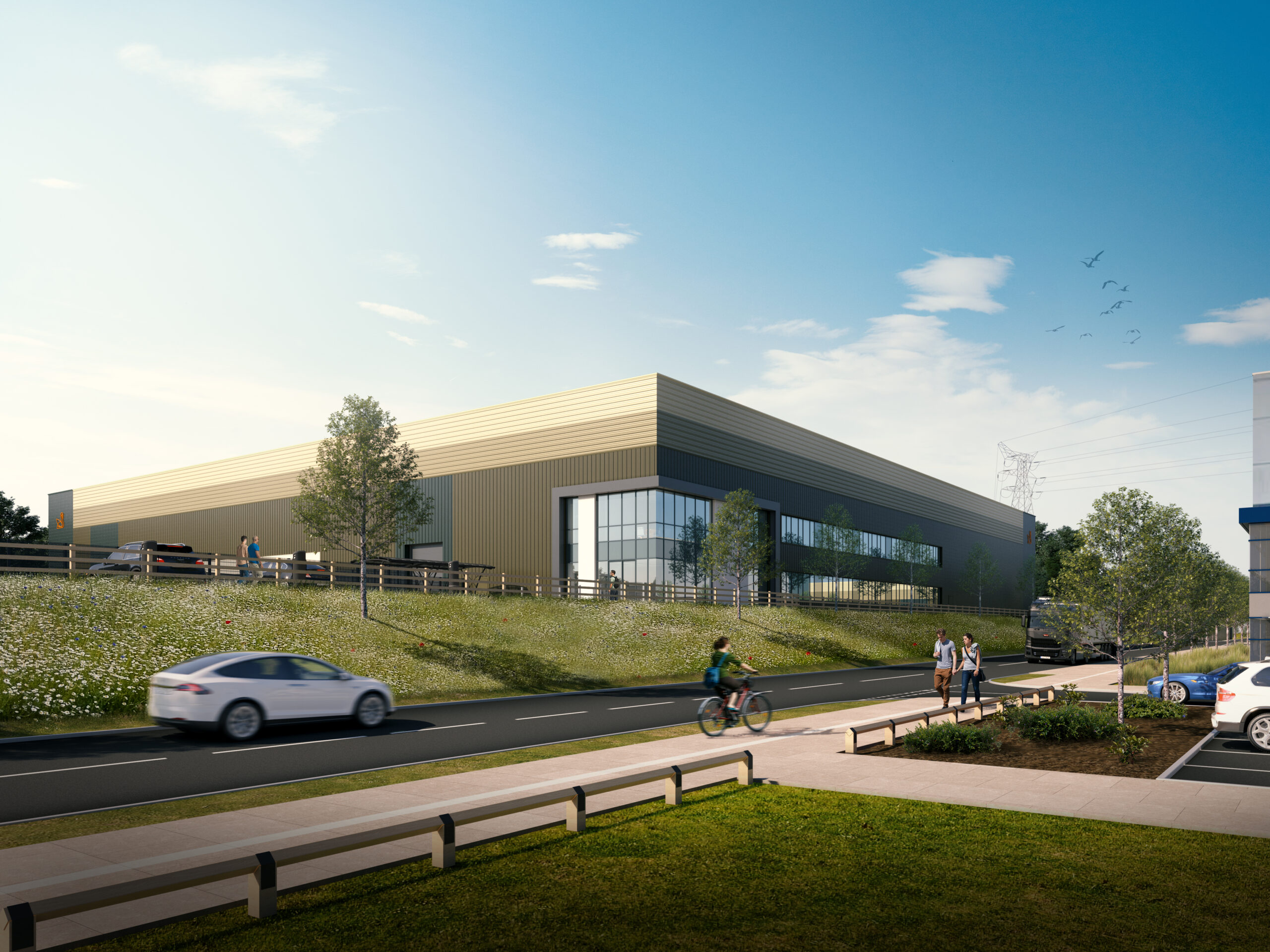

A customised, Build to Suit building option allows you to determine the physical size of the building, the height, the number and placement of dock doors, yard space and parking, and size of office space. More importantly you choose the power required to sufficiently run your operation, to avoid disruption but achieve optimal output. Wellbeing amenities such as green spaces, trim trails, outdoor gym equipment and seated picnic areas, can be tailored for your employees to enjoy during their breaks.

Finding the right building with a high labour pool and within easy access of your suppliers or customers is at a premium. An option is to seek land and build a tailored building in a preferred location. St. Modwen Logistics has a one of the largest land-banks in the industry and has worked with customers through planning, development and building processes to help customers achieve a fully tailored, sustainable operation, helping them increase operational efficiency and overall output.

Invariably achieving a tailored building in a preferred location can take up to 3 years, the way forwards is to plan ahead and work with a trusted partner with expertise of delivering modern, high-quality, sustainable buildings that meet operational, ESG and employee wellbeing needs.